Extrusions fill a void where standard fittings are not sufficient. They are versatile in size, spacing, number of outlets, etc. They are made in a way that their outlets are low stress, fatigue resistant construction. Various application benefits below:

- They can include tight center to center spacing, minimizing footprint.

- Flexible to your design and manufacturing code.

- The outlet removes the need for pipe and repad and converts this non-radiographable weld into fully radiographable butt-welded connection.

- The design can minimize the number of girth welds needed with Tee based manifold design.

- Radial or tangential design or both.

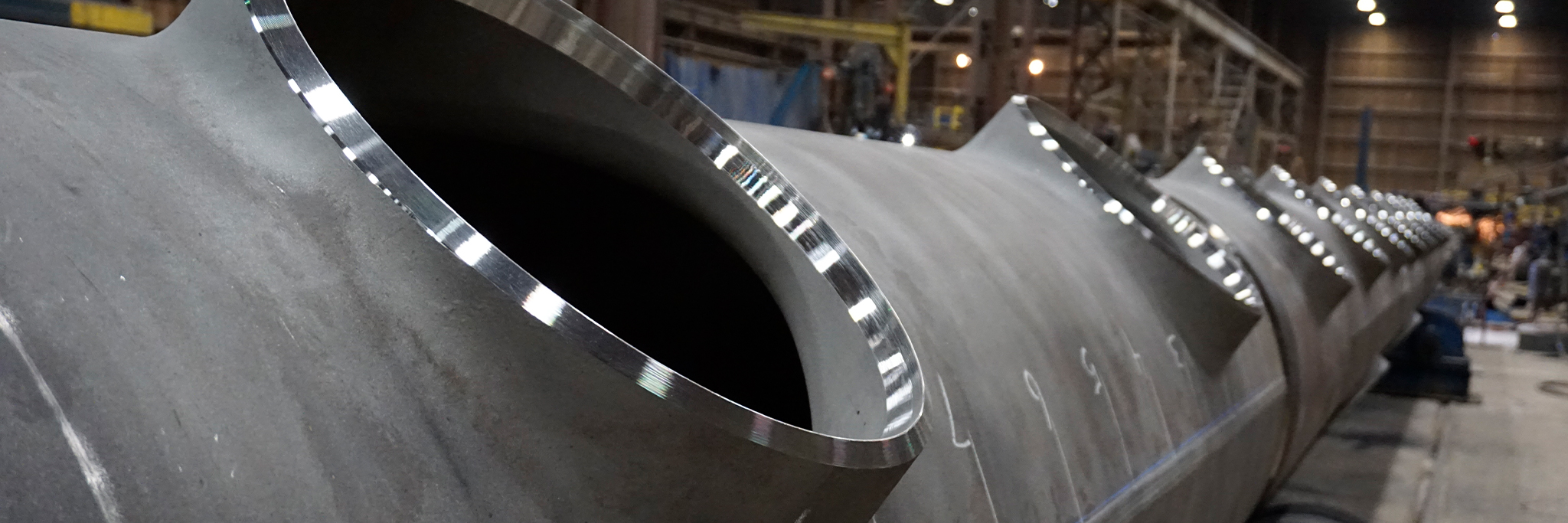

Extruded Tee and Header Applications

Extrusions vs. Tees

Extrusions

- Extrusion is a self-reinforced fitting based on conformance with code reinforcement formula.

- Extruded fittings are flexible with no minimum outlet diameter and additional fabrication allowed within reinforcement rules.

- Initially – Proof Testing.

- Code Case 52 to B31.1 (“K” Factor)

- B31.1, B31.3, B31.4, B31.8

- Additional connections can be added to the fitting after installation.

Tees

- Tee wall thickness is based on burst testing data and extrapolation.

- Tees must meet strict dimensional guidelines with one outlet and no other attachments like o-lets, etc.

- Minimum outlet diameter is one pipe size below half of run diameter.

- Can be purchased “off the shelf.”

Extrusion vs. Welding

Extrusions

- Made from a single piece of material

- No welds

- Uniform grain structure

- Resistant to heavy loading and cyclic service

- Limited fabrication required

- Less material than a weld

- No HAZ (heat affected zone)

Welding

- Reinforcement pads are non-radiographable.

- Require greater thickness.

- Create high stress corner joints and exposure to fail in HAZ (heat affected zone).

- More fabrication and material than an extrusion.

- Lower external load factor rating.

- High chance of failure in cyclic service.