Our Process

To be the recognized leader in the supply of process and material solutions to our energy and industrial partners worldwide.

3 Step Process

CONSULT

Our expert team collaborates with you to understand your unique requirements and provide tailored solutions that align with your project’s needs.

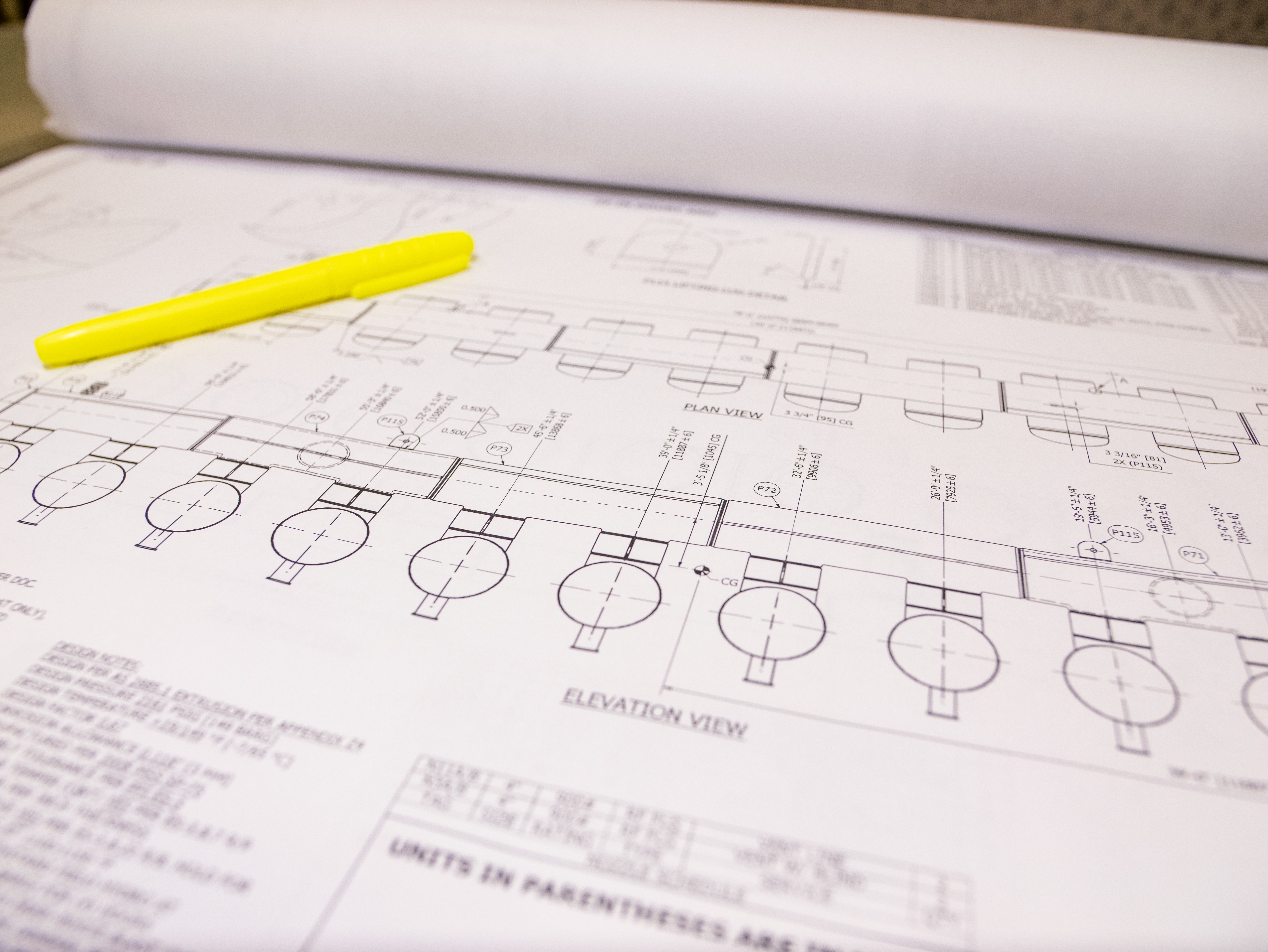

ENGINEER

We leverage cutting-edge technology and industry expertise to design precise, high-quality engineering solutions that meet the highest standards of performance and efficiency.

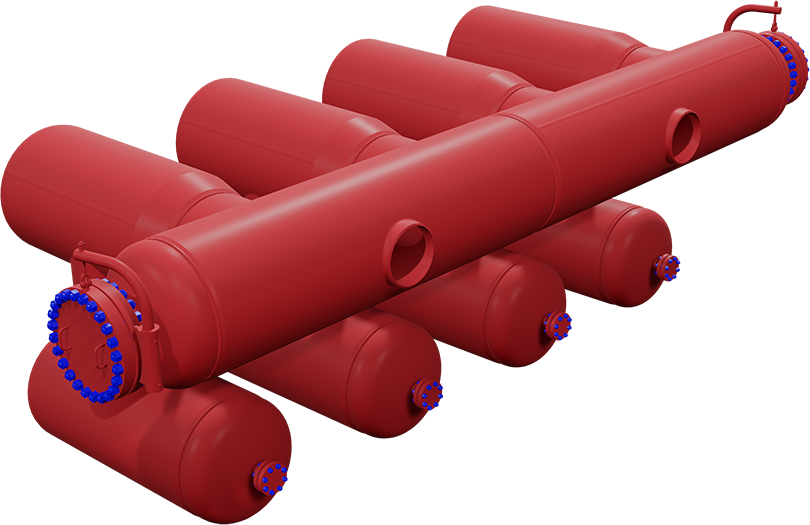

FABRICATE

Utilizing state-of-the-art equipment and materials, we bring your vision to life with precision fabrication, ensuring durability, accuracy, and excellence in every finished product.

More Than A Fabricator

Taylor Forge pursues excellence in engineering, quality control, fabrication, and project management to deliver exceptional results on critical projects. By controlling every stage of the process—from design and planning to precision fabrication and on-site execution—we ensure unmatched consistency, accountability, and performance. Our in-house capabilities allow us to tackle complex challenges with agility and innovation, setting new standards for excellence while meeting the most demanding specifications with confidence and precision.

Our Services

Engineering

Our reputation is built on decades of outstanding performance driven by the dedication and expertise of our exceptional engineering team. Our engineers combine deep technical knowledge with hands-on experience in solving real-world engineering challenges. Leveraging cutting-edge tools like advanced CAD platforms and process design analysis software, we transforms complex concepts into practical, high-performance solutions. Backed by an industry-leading staff of degreed engineers, metallurgists, and quality control specialists, we deliver unwavering support from initial design through final delivery.

Project Management

Our dedicated project managers are the driving force behind keeping projects on track and pushing through adversity with determination and precision. They serve as the vital link between our customers, partners, and internal teams—coordinating efforts, managing timelines, and ensuring clear communication every step of the way. Whether navigating tight deadlines, unforeseen challenges, or complex specifications, they bring the insight and adaptability needed to overcome hurdles. By collaborating closely with both shop and office personnel, our project managers ensure that every job moves forward smoothly, efficiently, and with a shared commitment to success.

Quality Assurance

Our Quality Assurance department provides unwavering support through every stage of a project, ensuring that nothing is left to chance. With meticulous testing, thorough documentation, and a steadfast commitment to rigorous industry standards, they uphold the integrity of our work and the trust of our clients. Their attention to detail and dedication to excellence are critical in delivering products that meet the highest expectations—every time.

Our in-house testing laboratory capable of a variety of destructive testing requirements. Capabilities include tensile and weld bend tests, Charpy impact tests, hardness tests through Rockwell and Brinell machines, and mass spectrometry. Quality is verified by in-house Level III inspection and a resident Authorized Inspection Agency. Processes performed by Taylor Forge inspectors include radiography (RT), magnetic particle (MT), ultrasonic (UT), dye-penetrant examination (PT), visual examination (VT), and positive material identification (PMI).

Fabrication

At Taylor Forge, our comprehensive fabrication process is the result of decades of dedication, refinement, and hands-on expertise. From thick-wall rolling and precision welding to machining, heat treatment, blast and paint, and expert material handling, we offer a full suite of in-house capabilities tailored to the most demanding applications. This high level of service is made possible by the unwavering commitment of our skilled tradesmen and shop foremen, who foster a culture where craftsmanship, pride, and continuous improvement are part of every job. In our shop, quality isn’t just a standard—it’s a shared responsibility.