Vortex Tube

Compact high-performance separators

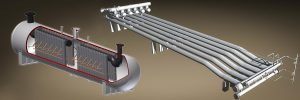

Fine Particle Separation in a Reduced Footprint

Taylor Forge Vortex Tube Technology leverages high velocities to reduce both the diameter and overall footprint of separators compared to conventional vane, mesh, and coalescing designs. Available in both standard and knockout configurations—with horizontal and vertical orientations—the tube design offers a low-cost, low-maintenance solution that’s easy on operations and your budget.

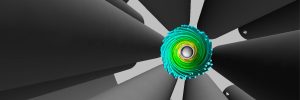

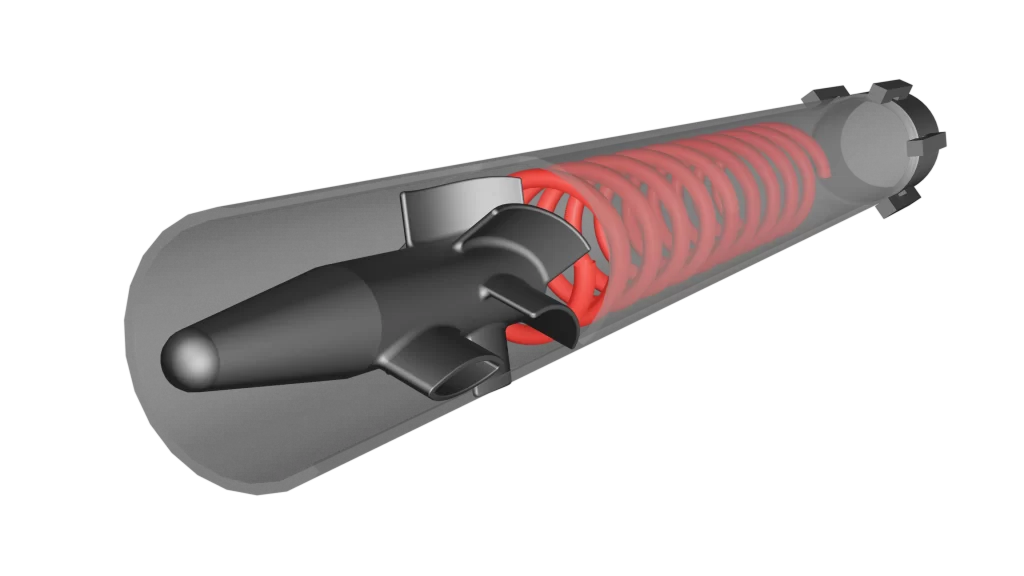

The Whirly Jig

Patented and designed to generate high g-forces, the Taylor Forge Whirly Jig design utilizes recycling gas as motive to separate and drain liquids out of the separation tube.

Maintenance Free

With no moving parts, the Vortex Tube Separator is easier on operations, your budget, and the environment.

Overview

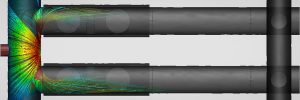

THE PROCESS DESIGN

High velocity gas and liquid cross the whirly jig’s fixed vane assembly inducing a high g-force tornado inside the separation tube. These forces combined with the contrasting densities and specific gravities of the process stream, forces the heavier liquids to the tube wall while the gas stays in the low-pressure core of the tube. The liquids then leave out the gap via the 8-10% motive gas that recycles back to be cleaned once more. With a fixed pressure drop based on the highest possible volumetric flow rate and turn down needs, the vortex tube design can be customized to achieve up to 90% turndown ratios.

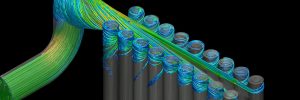

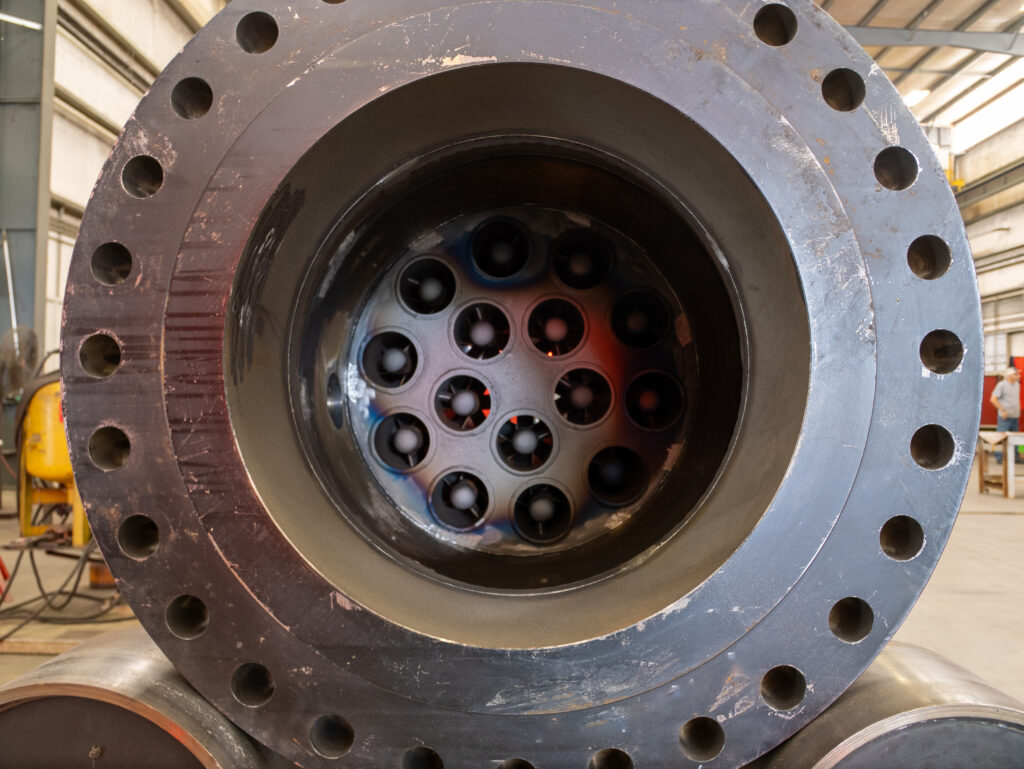

SOLUTIONS TO MEET YOUR PROCESS FLOW NEEDS

The Taylor Forge Vortex Tube Design is flexible in orientation. The whirly jigs can be aligned in single-tube and multi-tube arrangements both in horizontal and vertical alignment. With minimal cost differences and without the need for a quick opening closure, significant cost-savings is realized. Depending on your process stream flows, a knockout sections and two-zone control systems can be applied to handle surges or small slugs of liquid that may arrive at your separator.

Wide-Ranging Separation Solutions

The Vortex Tube design is capable of separating a wide range of liquid and gas streams—including water, steam, natural gas, various lubricants, and more. Commonly used at inlets and mid-process locations in compressor stations, gas plants, amine treaters, dehydration units, and fuel gas skids, Taylor Forge can design a compact separator tailored to your specific needs.