Vortex Cluster

High efficiency bulk separation

High Efficiency Bulk Separation

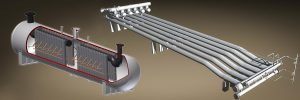

Taylor Forge Vortex Cluster Technology uses an internal piping system to generate a tornado effect within the tubing, mechanically separating liquids from gas. Developed and patented over 50 years ago, the cluster design is built to handle bulk liquids and solids, while also effectively reducing foaming in hydrocarbon separation applications.

Slug and Surge Handling Expert

Specifically developed for handling slugs of liquid. The cluster system will process your liquid while creating a calm interface reducing foam and lowering necessary residence time.

Maintenance Free

Taylor Forge Vortex Cluster Technology incorporates an internal piping system to create a tornado inside internal tubing to mechanically separate out liquids from gas. Developed and patented over 50 years ago, the cluster system is built to handle bulk liquids, solids, while also adept at reducing foaming in hydrocarbon separation applications.

Overview

THE PROCESS DESIGN

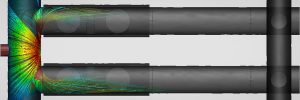

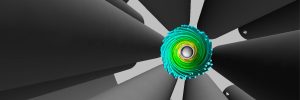

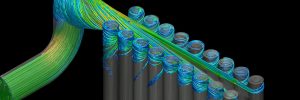

Utilizing an internal piping system to control and achieve velocities, your process stream will enter into the tubes of the cluster through a large tangential gap. This induces a tornado within the controlled environment that mechanically forces the heavier liquids to the wall of the tubes while the gas rises through the low-pressure core and exits via the vertical section. An internal baffle system ensures equal distribution across all tubes.

SOLUTIONS TO MEET YOUR PROCESS FLOW NEEDS

The cluster design features tubes ranging from 6” to 24” in diameter, allowing the separator to handle a variety of flow rates, process fluids, and 2- or 3-phase flows. The cluster tubes are always positioned vertically to use gravity for liquid drainage, while the overall vessel can be oriented either vertically or horizontally.

UNIQUE SEPARATION SOLUTION

The cluster design offers a unique solution for hydrocarbon separation applications. It effectively reduces foaming, minimizes vapor space compared to Stoke’s Law, and handles large surges and solids. Often, this technology can replace multiple separators within a plant layout—commonly combining an empty slug catcher and downstream inlet separator into a single unit. This consolidation can result in significant installed cost savings for your project.