Offshore Platform Equipment

ENGINEERED SOLUTIONS

ENGINEERED SOLUTIONS

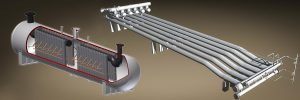

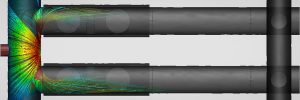

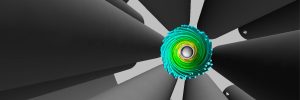

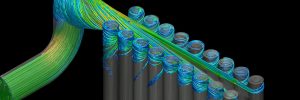

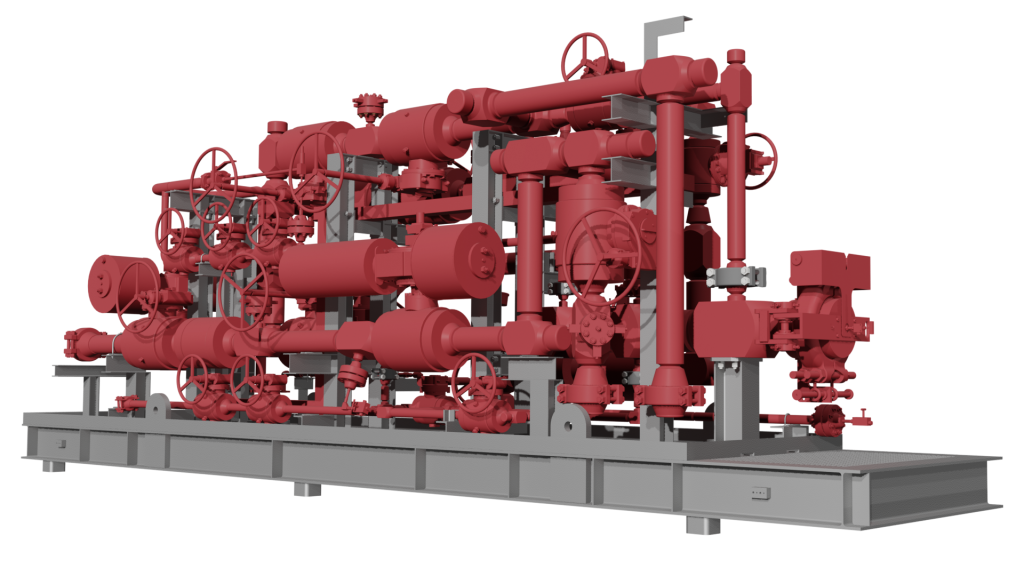

Taylor Forge has been involved in the design and manufacturing of components and skid mounted equipment since the mid-1950’s and continues to be an industry leader today. As new technology has allowed producers to go into deepwater regions to find oil and gas, Taylor Forge has been the trusted vendor for up to 20,000psi solutions for offshore applications. TFES’s design and fabrication capabilities and high-pressure experience have allowed pigging technology to keep up with this ever-evolving market. We have the capability to hydrostatically test assemblies to 50,000 psi. Requiring the application of various pipeline codes and appendices, offshore equipment requires a level of engineering and fabrication quality that is beyond that of your typical fabricator. With numerous metallurgical engineers on staff, Taylor Forge has the in-house testing and shop capabilities for designing and fabricating high yield fittings and vessels that is not scene in the industry.

DESIGN EXPERTIESE

Experienced engineers that are approved to work with B31.3 Section 9 code requirements

DEPENDABLE QUALITY

In-house testing and heat treating means we control our products quality, not our vendor’s quality.

Overview

OUR EXPERIENCE

Our proprietary High Strength Low Alloy (HSLA) forging materials, have been developed by Taylor Forge Engineered Systems (TFES) for use in high pressure applications requiring high strength, excellent toughness, and good weldability. Taylor Forge’s unique HSLA forging materials are intended to be the starting material for components certified to MSS SP-75, CSA Z245.11, ASTM A-694, ISO 15590, and API 6A for grades up to 80ksi yield strength.

Since 2000, TFES has supplied more than 720 tons of high pressure components using our proprietary materials for customers such as: BP America, Chevron, Shell Deepwater, Petrobras, SBM Atlantis, Andarko, Williams, and FMC. To view all informational PDF’s available please visit our Resources section.