NACE Region III Sour Service Slug Catcher. Fittings were designed with low sulfur content and went through a rigorous HIC testing procedure. PWHT on all manifolds and SPWHT of the line pipe. Location: Texas Design: (1) 8 Finger Slug Catcher Design Pressure: 1440psig Gas Flow: 850 … [Read more...] about Texas 8 Finger Slug Catcher 2024

Project Highlights

Texas 6 Finger Slug Catcher 2025

With over 4000bbls of storage this 6 Finger Slug Catcher was an ideal solution for a gas plant in the Permian Basin. Location: Texas Design: (1) 6 Finger Slug Catcher Design Pressure: 1440psig Storage: 4500bbls Gas Flow: 240 MMSCFD Specials: Single Downcomers Line Pipe: 48″ API … [Read more...] about Texas 6 Finger Slug Catcher 2025

Peru 4 Finger Slug Catcher 2024

Modular Front-End design and fabricated to minimize field work at the Peru job site. Utilized specialty extruded fittings to meeting 900# ANSI design pressure Location: Peru Design: (1) 4 Finger Slug Catcher Design Pressure: 2000psig Storage: 500bbls Gas Flow: 94-135 … [Read more...] about Peru 4 Finger Slug Catcher 2024

Qatar 4 x 12 Finger Slug Catchers

The largest project to date in the Qatar Ras Laffan region. These slug catchers were designed to NACE Region III specifications. The starting material was all HIC and SSC tested. The liquid and hydrocarbon manifold incorporated Inconel cladding and overlay to help mitigate corrosion in this … [Read more...] about Qatar 4 x 12 Finger Slug Catchers

Texas 4 Finger Slug Catcher 2025

With over 2000bbls of storage this 4 Finger Slug Catcher protects a gas plant in the Permian Basin. Location: Texas Design: (1) 4 Finger Slug Catcher Design Pressure: 1440psig Gas Flow: 750 MMSCFD Specials: Double Downcomers Line Pipe: 48″ API 5L Line Pipe … [Read more...] about Texas 4 Finger Slug Catcher 2025

Louisiana Slug Catcher 2021

Built to minimize field work, this double downcomer assembly shipped in (3) main manifolds. The front manifold to the double downcomers significantly cuts down on fit up in the field. Delivered in <20 weeks this project helped support the aggressive project schedule set forth by the … [Read more...] about Louisiana Slug Catcher 2021

High Pressure Offshore Separator Vessel 2020

Designed and fabricated for a critical path offshore project. The vessel utilized TFES’ ability to work with a HSLA that made the vessel thinner and lighter. This was a highly spec’d job due to the high pressures and volatility of offshore equipment. Location: Gulf of Mexico Design: High … [Read more...] about High Pressure Offshore Separator Vessel 2020

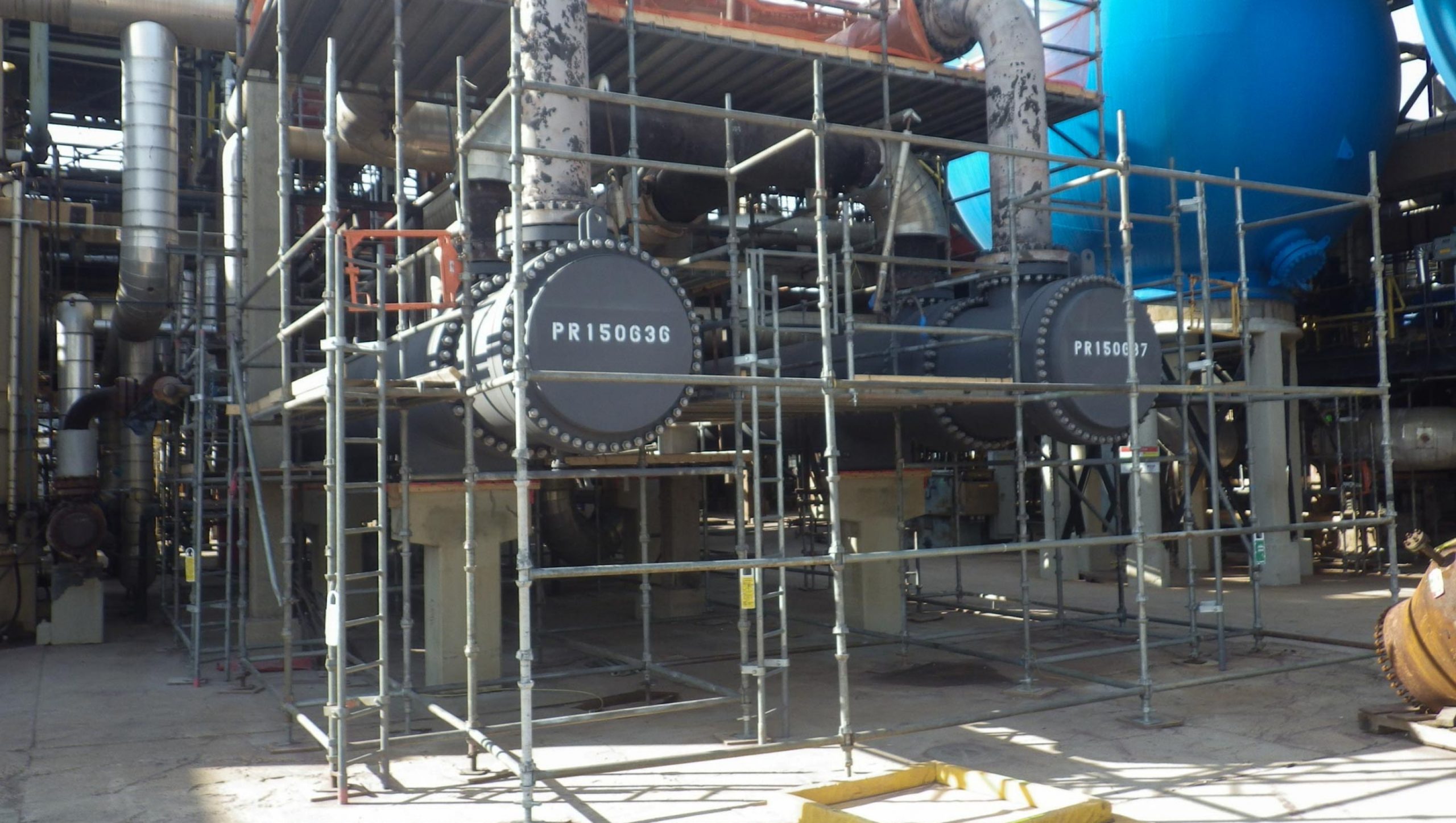

Ohio Chrome Exchangers 2019

TFES was asked to fabricate (2) new chrome exchangers to replace existing units. This requires precise fabrication to allow seamless fitup into the existing locations. Additionally, the 934 specifications add a layer of fabrication complexity necessary for chrome applications. Very specific pre and … [Read more...] about Ohio Chrome Exchangers 2019

Oklahoma Slug Catcher 2019

The third 2-finger slug catcher delivered to this site, this slug catcher has been designed for the fasted and most cost effective installation. The wet gas inlet and dry gas outlet, usually 2 pieces, were fully welded and assembled at the TFES facility in Paola, KS. This allowed for the shipment of … [Read more...] about Oklahoma Slug Catcher 2019

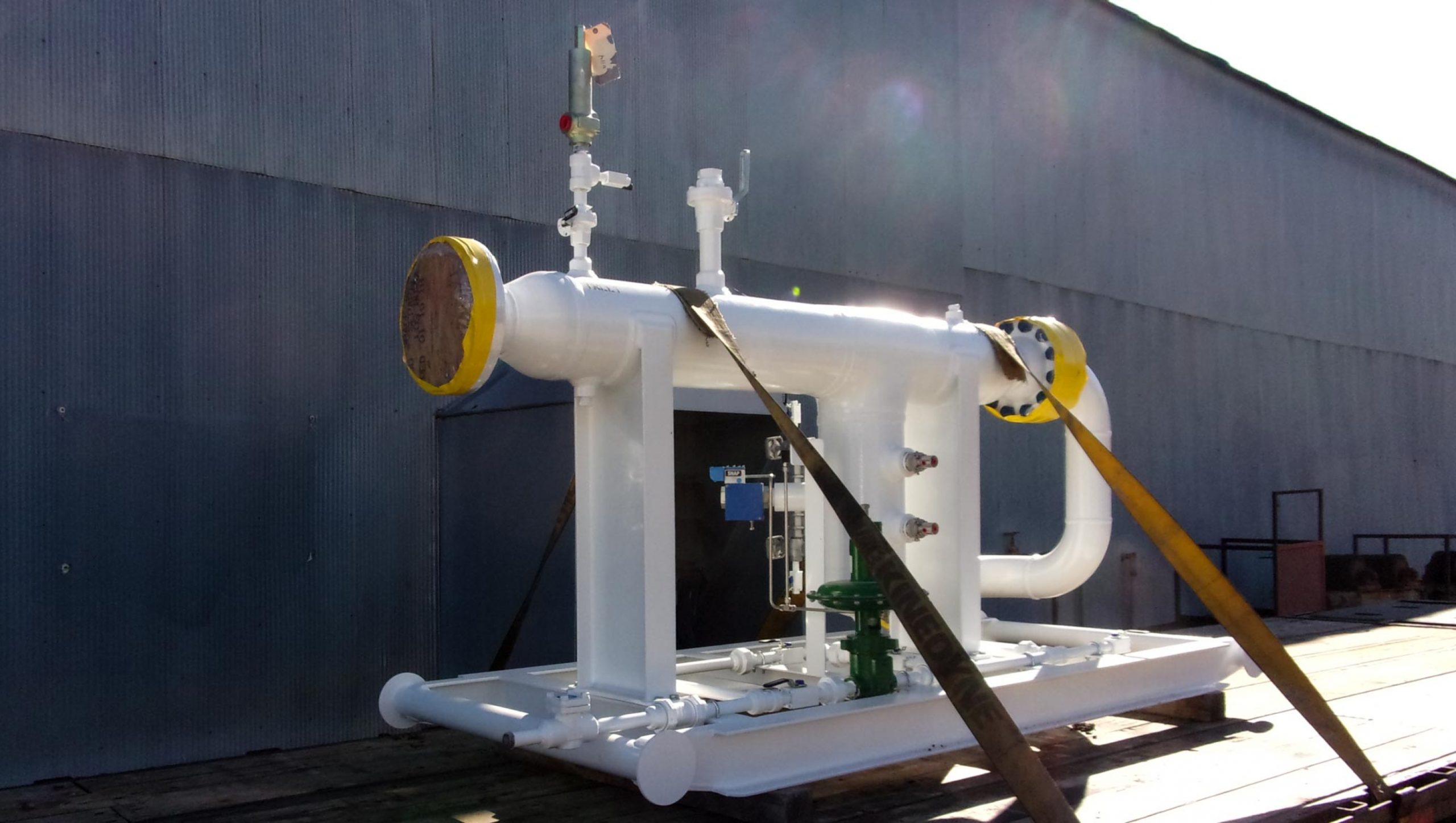

Wellhead Vortex Separators 2019

Mechanically and process designed by Taylor Forge, these standard vortex tube units are able to handle varying gas flows with simple ease and can achieve >1 micron separation. These units replaced filter units that were having repeated cartridge problems. Vortex requires no regular maintenance, … [Read more...] about Wellhead Vortex Separators 2019

Vortex Cluster Slug Catchers 2019

Mechanically and process designed by Taylor Forge, these vortex cluster units are able to handle large liquid surges experienced during pigging events. By combining the high efficiency separation of vortex clusters with the size and storage of a large vessel, the customer was able to eliminate … [Read more...] about Vortex Cluster Slug Catchers 2019

Aerospace Vessels 2019

These (4) vessels were fabricated out of high strength low alloy (HSLA) carbon steel to the NASA specifications. They require a high level of cleanliness and cyclic service. TFES has supplied to vessels for the Aerospace industry for over 60 years. Location: Cape Canaveral, … [Read more...] about Aerospace Vessels 2019

Canada Extruded Manifolds 2019

This was a critical path project delivery (12) manifolds to (6) different compressors stations. The CSA specifications utilize the full breadth of Taylor Forge’s capabilities from in house impacts tests to fully surveyed ovens for heat treating. Location: Canada Design: Aftercooler … [Read more...] about Canada Extruded Manifolds 2019

New Mexico Slug Catcher 2019

This project utilized a single slug catcher to cover (4) cryo trains being built at the site. Utilizing stock plate, the manifolds arrived on site in just 16 weeks with the total install completed in under 30 weeks. Location: Lea County, NM Design: (1) 8-finger slug catcher with double … [Read more...] about New Mexico Slug Catcher 2019

Iraq Slug Catcher 2015

In a collaboration between an American manufacturer, international oil major, and Eastern European freight provider, a slug catcher was air freighted to a petroleum development in Iraq. This schedule critical project was engineered, fabricated and delivered in under 24 weeks. Location: Majnoon … [Read more...] about Iraq Slug Catcher 2015

Mississippi Test Stand Vessels 2009

(9) Vertical Vessels built to the NASA specifications. As part of mission critical equipment, these vessels were fabricated at the highest level of quality. Location: Mississippi Test Facility Design: Water Run Tanks Storage: 39,000 gallons Design … [Read more...] about Mississippi Test Stand Vessels 2009

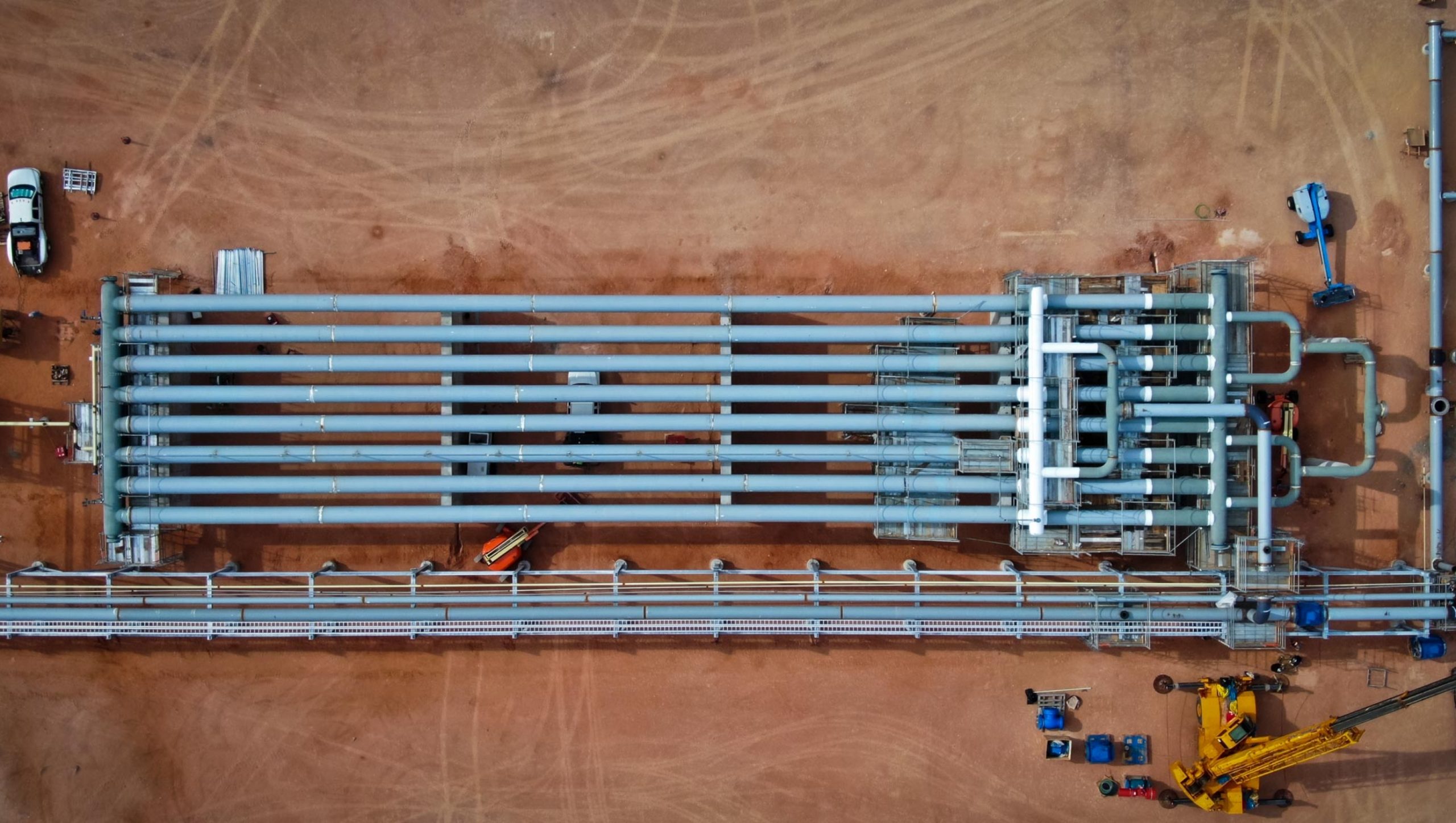

Australia Slug Catcher 2009

To minimize site fabrication the wet gas inlet and dry gas outlet manifolds were fully modularized in a yard in Corpus Christi. The module weighed over 800,000 lbs. The design incorporated 3-phase separation on the liquid end to help separate hydrocarbons from water and also allow for a corrosion … [Read more...] about Australia Slug Catcher 2009

Qatar Slug Catcher 2008

Two of fourteen (14) 3-phase slug catchers Taylor Forge has supplied to Qatar. The slug catchers support the largest LNG facility in the world. Due to the extreme conditions of the process fluids, the carbon steel plate was HIC and SSC tested, and portions of line pipe and liquid manifolding was … [Read more...] about Qatar Slug Catcher 2008

Vietnam Slug Catcher 2002

At high pressure and in sour service, Taylor Forge’s unique extrusion process allowed the use of high strength low alloy carbon steel fabrication, saving time and money. This Slug Catcher also included an isolated sludge manifold to aid in clean-out. Location: Vietnam Design: (2) 6 – … [Read more...] about Vietnam Slug Catcher 2002