Slug Catchers

Protecting downstream investments with unmatched design and quality.

Superior Design Meets Modular Innovation

Taylor Forge has long established itself the finger or harp slug catcher industry lead solution provider from small to large storage volume applications from sweet to the sourest process streams. Uniquely positioned with in-house engineering staff to meet your process design and metallurgical needs, Taylor Forge can truly say it has a solution for your needs. Utilizing the unique extruded header process, Taylor Forge offers a blend in savings that touch on manufacturing, fabrication, and install. With fewer overall manifold welds due to extruded outlet headers, and smaller footprints by avoiding standard tees and reducers, TFES reduces plot space widths by nearly 50%, leading to the lowest total install cost in the industry.

Critical Application Ready

Relied upon to protect some of the most critical LNG facilities worldwide, Taylor Forge has abundant experience meeting NACE Region 3 Sour Service specs for Carbon Steel and Cladded applications.

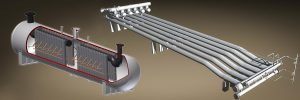

Harp, Vessel, L Type Assemblies

With the design and fabrication experience and capabilities delivering 300bbl to 50,000bbl slug catcher solutions, TFES will work with you to determine the right solution for your slug catcher application

Overview

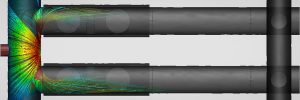

THE PROCESS DESIGN

At TFES, our slug catcher slows your flow, and allows for systematic separation and storage of gas and liquid in two distinct regions in the slug catcher. By always separating in an even number of fingers and balancing flow through multiple inlets, TFES ensures smooth flow into the slug catcher and proper distribution to the fingers. A downcomer in each finger ensures the bulk liquids are removed, followed by the application of Stoke’s law to account for particle fallout in the upper separation tubes of the slug catcher. Guaranteed to separate to 150 micron at design conditions and 100% gas flow, TFES provides a consistently reliable design that doesn’t cut corners and will handle your upset conditions without a carryover event.

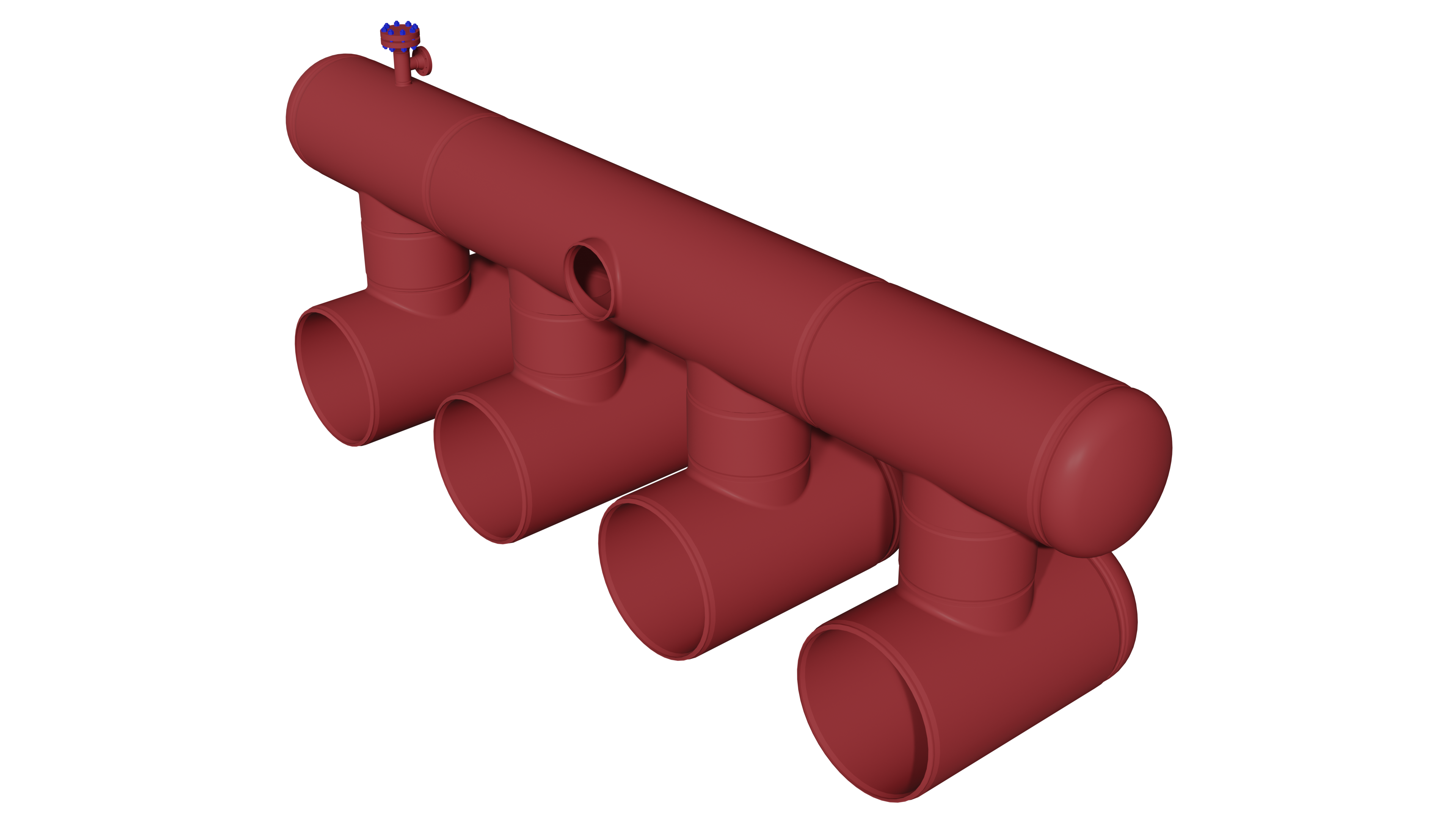

MODULAR EXTRUDED MANIFOLDS

The extrusion process allows TFES to overcome the limitations of B16.9 tees, such as fixed spacing, limited material options, and sizing restrictions, in favor of a uniquely customizable extruded manifold. This flexibility enables TFES to incorporate up to three outlets per manifold, significantly reducing the width of slug catchers—often by 10 to 20 feet. Additionally, TFES controls its sizing and heat-treating processes, allowing fittings with low-temperature requirements down to -50°F MDMT and diameters up to 54” to be produced with minimal additional cost or lead time. By avoiding the constraints of standard sizes, TFES reduces the need for reducers, anchors and supports (also manufactured in-house), and concrete foundations in the field. Post-weld heat treatment is performed in-house and comes standard on all slug catcher manifolds.

VERTICALLY INTEGRATED FABRICATION

As the only slug catcher supplier to design and fabricate entirely from flat plate, Taylor Forge maintains full control over the quality of every unit leaving our shop. With in-house rolling, welding, heat treating, X-ray inspection, Charpy impact testing, blasting, and painting, we ensure consistent excellence. By managing fitting chemistry, manifold yield, and final post-weld heat treatment and painting, Taylor Forge guarantees that quality is never compromised.