What is an Extrusion?

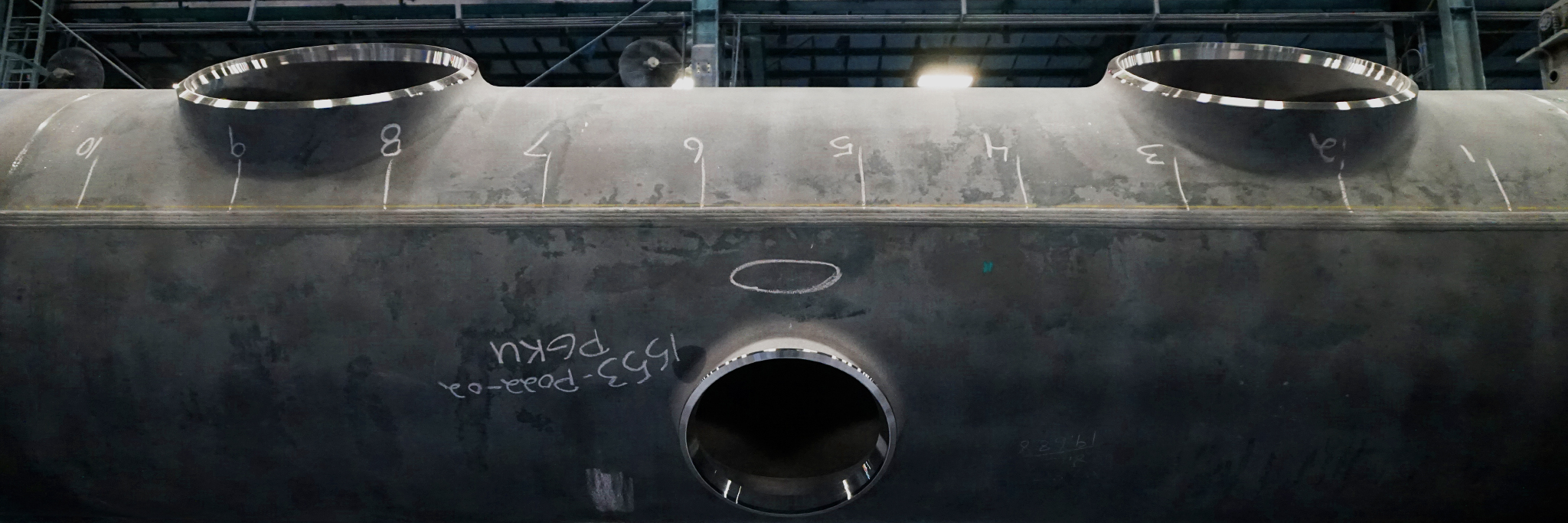

Taylor Forge Engineered Systems developed the extrusion process in the 1950s to fill a gap in reduced outlets that the standard and custom tee couldn’t supply. An extruded outlet is an opening in a cylinder wall made by forming the wall into an integrally reinforced branch connection. It is a low stress, self-reinforced connection designed in accordance with code reinforcement formulas rather than per burst test of a B16.9 Tee. In short, an extruded outlet is more dimensionally flexible than a Tee and more reliable than a welded connection that are typical for pipeline connections associated with these reductions.

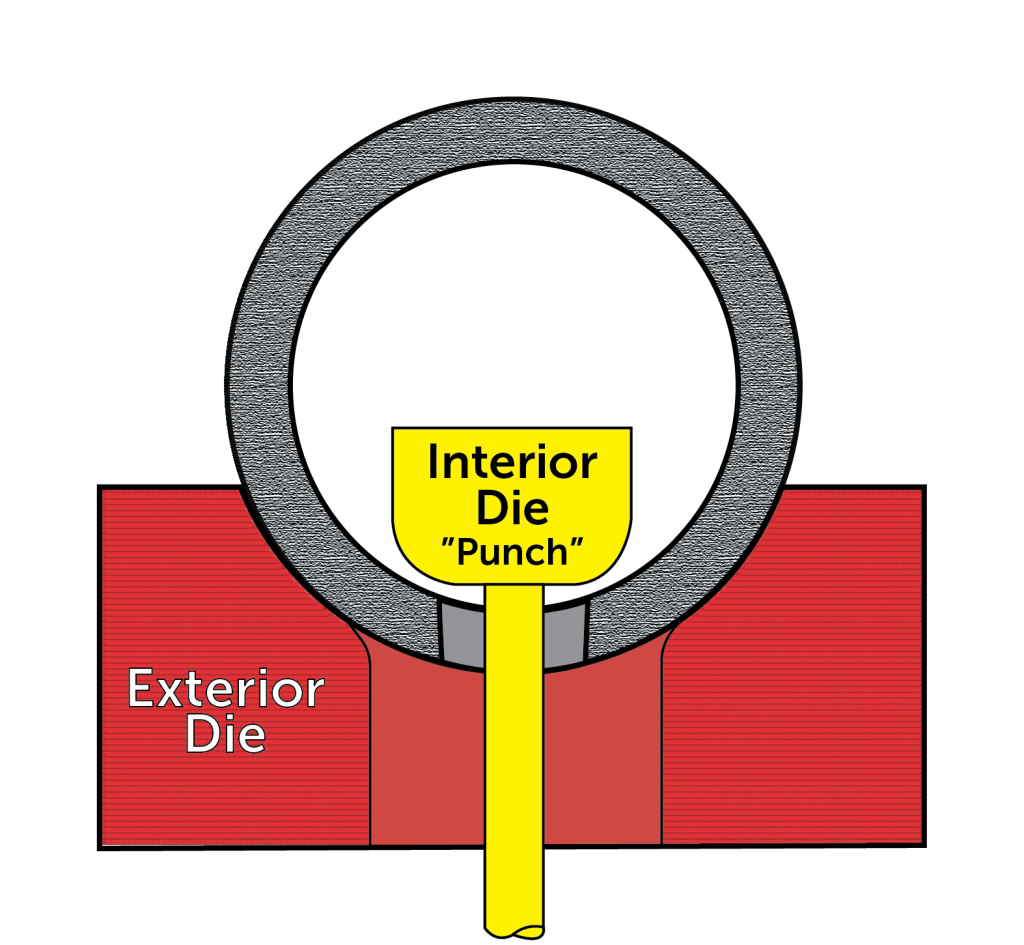

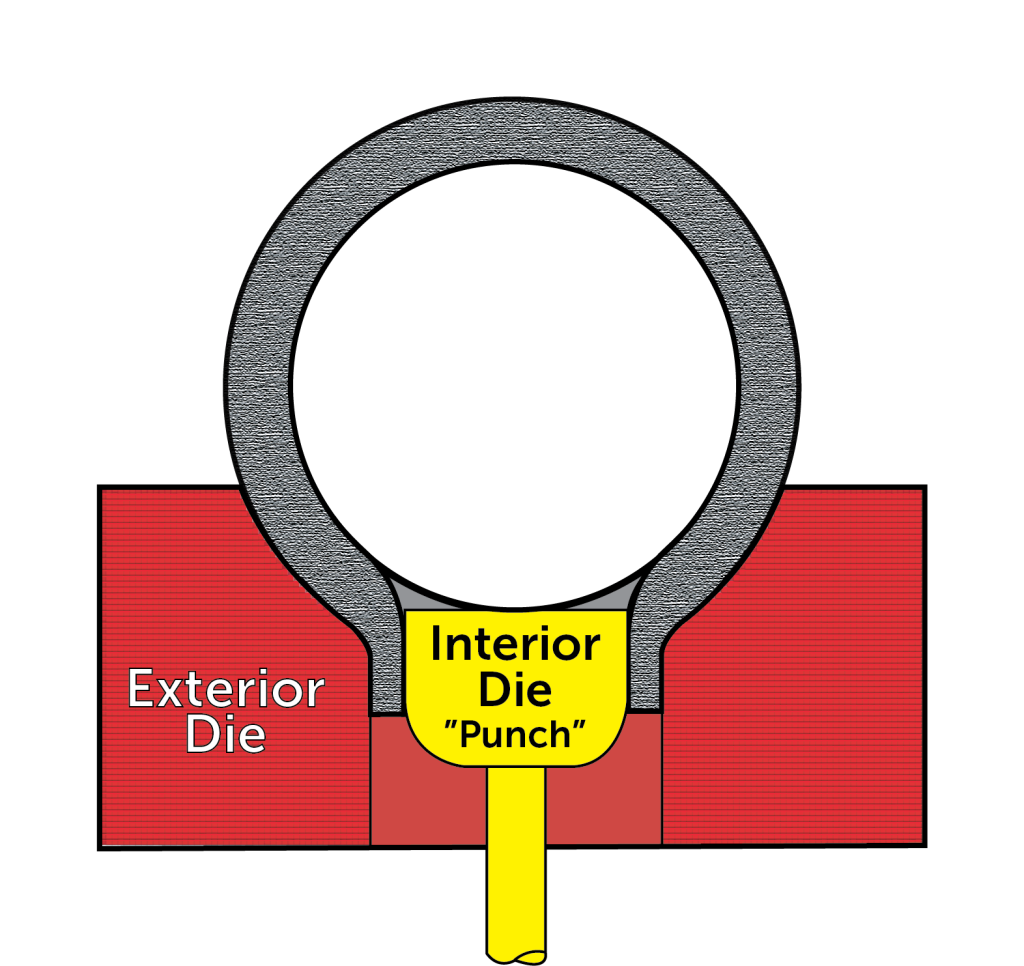

The extrusion process uses the heated of a pilot hole within a cylinder and an external and internal die to “pull” or “extrude” a smooth contoured hole from the excess pressure wall plate within the cylinder run/main line. An extruded header refers to outlets with beveled ends that are going to be installed into an assembly. An extruded manifold is a fully assembled piece that will be welded or flanged connected into another system.

Design Codes

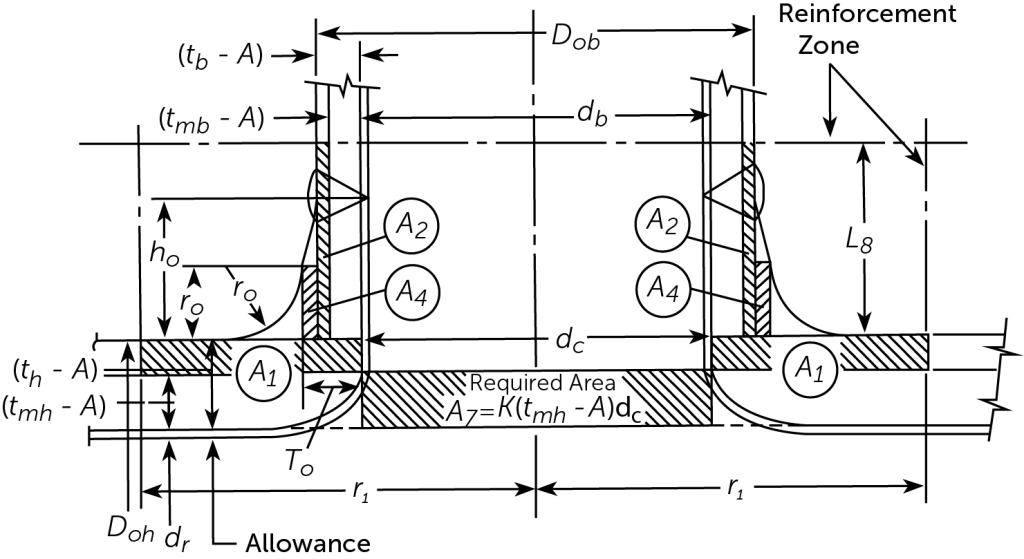

Extruded outlets can be designed to the Piping Codes – B31.3, B31.8, CSA – Z245.11, or even ASME Section VIII Pressure Vessel code. Formulas within these codes define the material thicknesses required to meet reinforcement code requirements (see fig. 2). Using proprietary internal and external dies, an extrusion supplier will ‘pull’ an extrusion out of thicker pipe that has final thicknesses that meet these specific design codes. The pipeline codes provide a credit in the reinforcement calculations for extruded connections. They also allow for high strength materials and wall thickness reductions. The credit plus use of high strength materials, provides significant cost savings in many applications when compared to Welded or Tee connections.

Manufacturing Codes

Extruded headers or manifolds are defined typically as a fitting. The fittings will typically fall into MSS-SP75, ASME B16.9, SA/A234 and /or ASME/ASTM specifications. The manufacturing code will define the type of materials, and the properties required for an extruded outlet to be considered a fitting per the specification.

Layout

Extruded outlets can be designed radially and tangentially along a pipe at any custom distance. The optimal center to center distance is (1) outlet diameter plus 2”. This is the minimum distance to be out of the reinforcement zone of the calculation. If you stay in the reinforcement zone, some additional thickness will be added. Ex: 30” pipe with 8” outlet can be 12” apart. TFES can roll plate up to the 13’ long. The more outlets you can place upon a single run, the more cost effective the design is compared to Tees or Welded connections. Extrusions help eliminate girth welds, saving money and time. As with ASME Section VIII, for connections 2” and smaller, no reinforcement is required.

Due to extruded outlets needing to be formed via an internal die, no size-on-size connections can be fabricated. This varies from a tee, which can be formed into a size-on-size configuration. For example, where a 36” outlet is needed out of a 36” run of pipe, we would size up the main run to 38” and swedge the ends.

Quality

Extruded fittings provide a butt-weld, fully radiographable connection. Because of the use of non-heat treated HSLA (high strength low alloy) plate, extruded fittings can be quench and tempered to meet the final mechanical properties of the site. This versatility allows the manifolds to meet low MDMTs (-50°F) and varying yield stresses (ex: X52,X70, etc) with relative ease.