1. Mechanical Design

All vortex slug catcher vessels will be designed to the ASME Section VIII Division 1 or Division 2 code. Depending on pressure and size, a division 2 design might be a good option to reduce cost. See our technical articles on ASME Section VIII Designs to pick the right code for you.

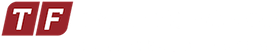

2. Vortex Cluster

This design works in 2-phase or 3-phase, flows can be pure liquid, pure gas, combination of liquid/gas, or any combination with solids. Ideal for separators that are going to see large slugs and surges of liquids.

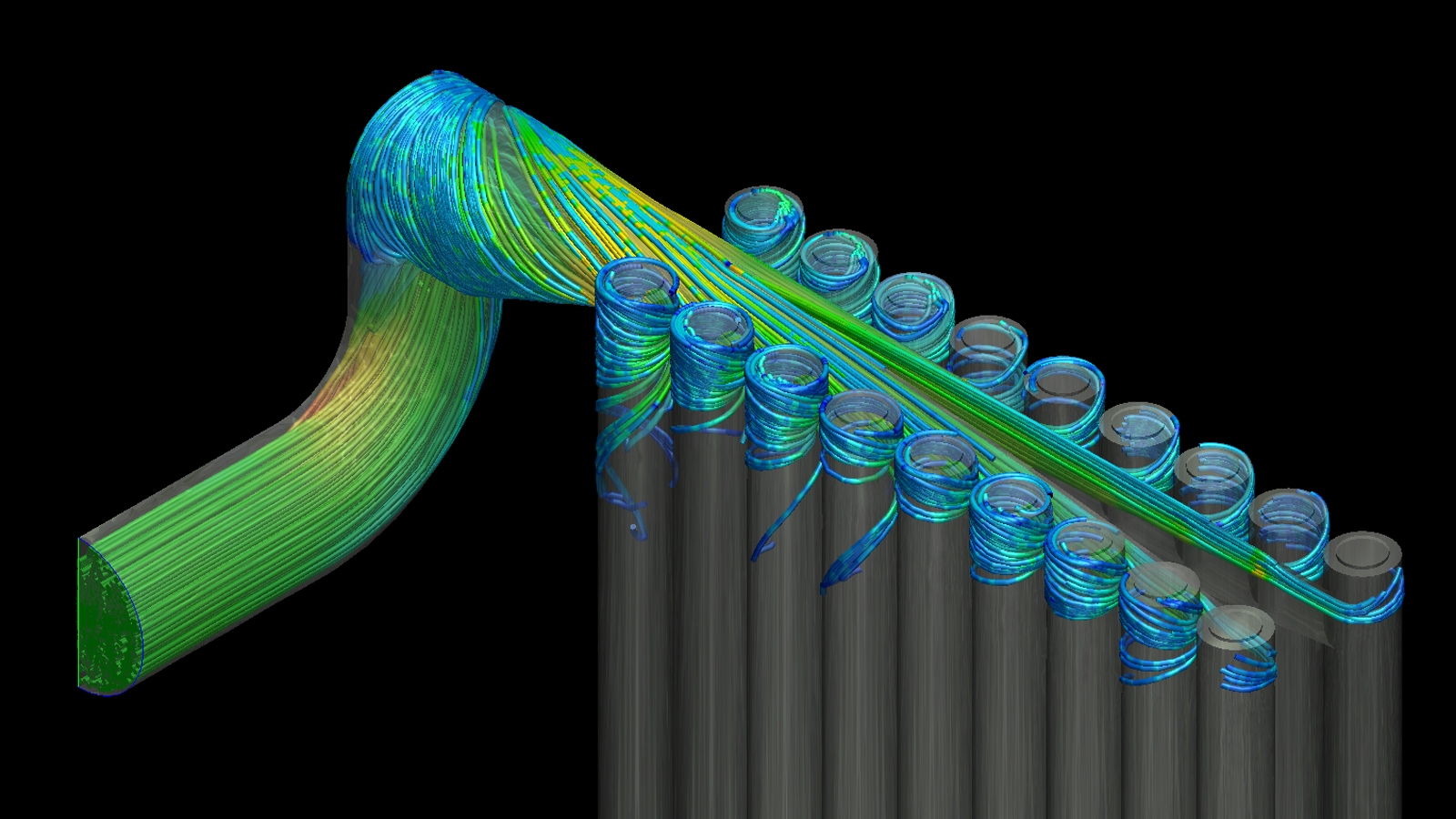

3. Vortex Tube

This design is generally used as a 2-phase scrubber. Sometimes to work as a liquid surge knockout / scrubber. It’s best used for high gas flow and lower storage requirements.

4. Design Advantage

The vortex or cyclone separation processes the gas faster, thereby reducing residence time, than a standard API 12J/Stoke’s law vessel. As such, the vapor space required in the slug catcher will be smaller reducing the size of the vessel. Additionally, the vortex will provide cleaner gas to your downstream filters, lengthening the life of their internals. See our vortex separation technical articles to learn more.

6. Low Maintenance

Unlike other high efficiency separation techniques within slug catcher vessels, a vortex system requires little to no maintenance. With no filter element and vanes (vane pack, demisters etc..) to foul up, operation is simplified for your operators. The cluster design is even capable of processing parafins, waxes, and other solids without fouling issues.

5. Separation Performance

A Vortex Slug catcher vessel can reach efficiencies of 99.9% removal of solids down to ≥ 0.3 microns and 99.9% removal of free liquids down to ≥ 1micron. See our vortex separation technical articles to learn more.

7. Single Source Vertical Integration

We do our own process design, fabrication, and testing in-house. That includes rolling, welding, heat treating, blast, and paint. This allows us to meet difficult impact tests, material chemistries, and overall quality levels unseen by many of our competitors. For information about procurement, check out our Procurement Prospective article.

WHY US

Taylor Forge Engineered Systems

has continued the reputation of traditionally dependable products

to a variety of industries.

Integrity

We don’t compromise our practices and we won’t cut corners.