1. Trusted Experience

With our first install in 1971, we are not a new player in the Slug Catcher industry. With over 130+ installs in front of Gas Plants and LNG facilities worldwide, our slug catchers have passed the true test of time with unmatched performance. Check out some of our completed jobs in our Project Highlights.

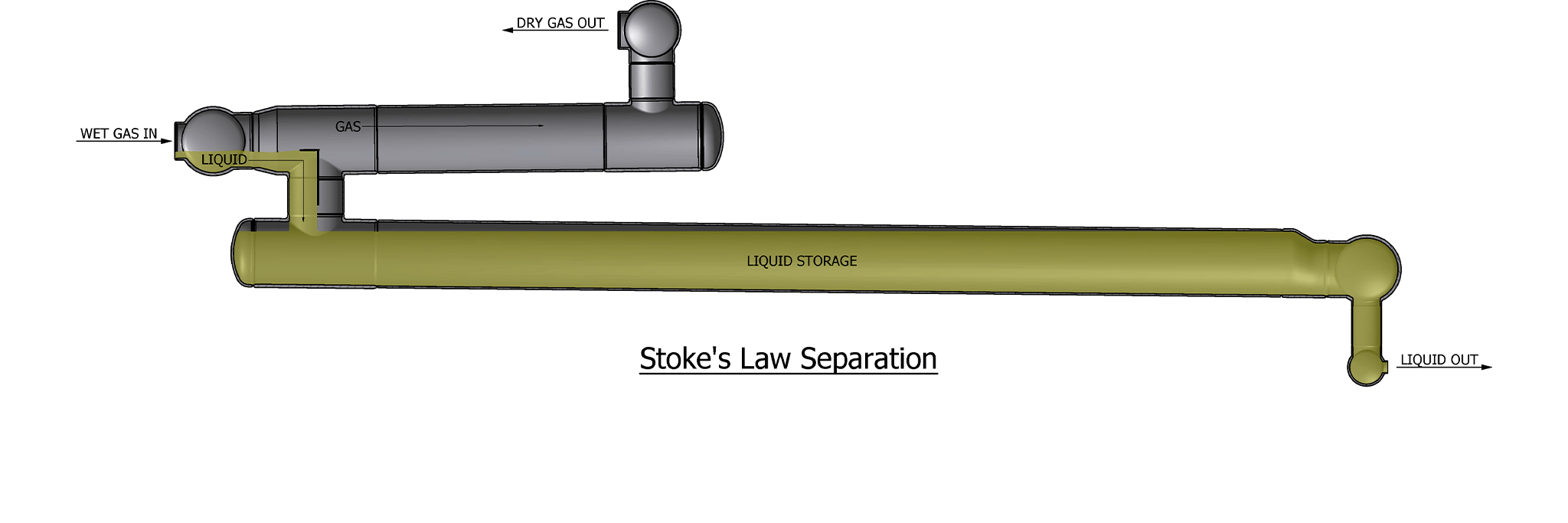

2. Stacked Design

We utilize a stacked design, wherein the gas separates in the upper fingers and storage occurs in the lower fingers. This allows for smaller plot space than the common Shell/DEP design by utilizing the lower fingers for only liquid storage. Most other designs in the market perform their gas and liquid separation in the same storage fingers. See our separation article to learn more.

3. Extruded Manifolds

Extrusions allow us to design fittings specifically for our customer’s slug catcher applications. By placing (2) outlets per fitting, our slug catcher is significantly less wide than all of our competitors. Additionally, this eliminates a girth weld per every per header, essentially requiring have the girth welds of the standard tee design. This saves money by shrinking the plot space as compared to standard Tees and also allows for lower cost customization to various sizes, yield strengths, and MDMTs (as low as -50°F without special pricing). See our many extrusion articles to learn more.

4. Single Source Vertical Integration

Our slug catcher is manufactured and fabricated at our Paola facility where it starts out as raw plate from the mill. The rolling, welding, heat treating, X-ray, charpy impacts, blast and paint all are done in-house. We don’t rely on other shops to meet our quality expectations, we go above and beyond the needs of the customer. For information about procurement, check out our Procurement Prospective article.

5. Balance and Symmetry

Our design incorporates an even number of fingers for proper distribution. Our large cross manifolds help balance the flows to make sure carryover and maldistribution are avoided. You won’t find a 3 or 5 finger TFES slug catcher. See Balance and distribution to learn more.

6. Stoke’s Law

The upper fingers on our design operate under Stoke’s law of separation. The gas particles separation is calculated to meet the desired micron size as specified by the customer. See our separation article to learn more.

7. Lead Time

We stock plate in our Paola facility to support your fast turn projects. We’ve delivered slug catchers to site in as little as 14 weeks.

WHY US

Taylor Forge Engineered Systems

has continued the reputation of traditionally dependable products

to a variety of industries.

Integrity

We don’t compromise our practices and we won’t cut corners.