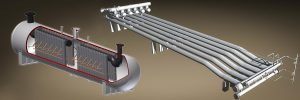

Finger or Harp Style Slug Catchers represent a unique challenge for engineering, project management, and purchasing for gas processing plants. Pricing is equally driven by shop fabrication and field installation. Requiring careful process design and complicated field installation, there are many things to consider to economically meet you processing needs without breaking the bank.

1. Plot Space

1A.

A long and skinny finger-type slug catcher is going to be your most economical design. You’ll need to evaluate the plot space vs. the liquid hold-up requirements to determine what length your site can support. Pipe is cheaper than manifolds, so reducing fingers by making the unit longer (when the gas flow allows) will achieve superior economics. If the gas flow dictates you only need a 4-finger slug catcher, you should challenge your engineers to find space for the unit, so you don’t have to bump up to 6-fingers. That can be accomplished by using a larger diameter storage pipe or making sure you have the correct coincident gas flow and operating pressures. In some cases, purchasing more land is cheaper than adding fingers.

Less fingers = Less $$$ – The less fingers you have, and therefore the longer you can make the unit, the more money you’re going to save. Storing 5000bbls of liquid in 6 fingers at 500ft is going to be cheaper than storing 5000bbls of liquid in 8 fingers at 400ft. This is because the cheapest part of a finger type slug catcher is the line pipe.

1B.

Extruded manifolds save significant space as compared to B16.9 Tees and pipe-based designs. Taylor Forge designs its slug catchers with 12-13’ cylinders that greatly reduce girth welds as compared to other designs. Our outlet center to center spacing is significantly less than that of our competitors. This adds up to very significant savings in concrete and structural steel during installation. A Taylor Forge 4-finger slug catcher will always being narrower than a competitor’s 4-finger slug catcher.

1C.

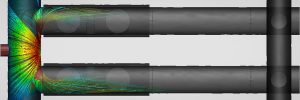

The hidden cost of a harp slug catcher is the height of the foundations or structural steel for the manifolds. The Shell DEP or Stratified flow design requires an increased 7:100 slope over the 1:100 Taylor Forge design. This can lead to 10-20’ in additional height over the length of the slug catcher. Expect this design to require more concrete and steel to install. Make sure you specify the slug catcher provider when getting a quote. All quotes will not be as short or narrow as the Taylor Forge design.

2. Delivery

Slug catchers deliver staggered in pieces rather than fully assembled. It is common to receive the anchors and supports well ahead of the manifolds and line pipe. Typically, the line pipe is needed next for installation, and finally the manifolds arrive to complete the installation.

It is typical in the US market to need your slug catcher operational in 30 weeks. Manifolds for a finger slug catcher, assuming typical 300# or 600# ANSI standards, can be delivered to hit this schedule.

If you’re on a tight schedule, line pipe out of distribution can be at your site in 6-10 weeks (note: if you have greater than 3000bbls of line pipe, you’ll most likely need a mill run requiring a longer delivery).

The anchors and supports required for your line pipe will be available some 10-16 weeks ARO.

The fittings or fabricated headers you purchase can be to your site in 16-20 weeks ARO. You should note though, you’ll be paying a premium for that 20-week delivery. See Line Pipe Considerations for why?

3. API 5 Line Pipe Considerations

The single easiest way to save money on your project is foreign line pipe. The most typical sourcing locations are South Korea, Germany, Japan, and the UK. For 42”, 48”, 54”, and 60” you’ll find significant savings going overseas. In fact, your vendor will likely be unable to source domestic pipe over 42” in the quantity required. It will save you around 15-20% to purchase foreign mill line pipe.

- Domestic Line pipe Diameters: 36”, 42” – In stock typically 6–12-week delivery

- Import Line pipe Diameters: 42”, 48”, 54” – 18-24 weeks

Note: When we say foreign sourced line pipe, we mean sourcing directly from a mill. The pipe your fabricator purchases ‘domestically’ is most likely also fabricated in South Korea, it just happens to be bought and stored in the US prior to being sold. At this time, no domestic line pipe mills will manufacturer pipe greater than 1” thick.

4. Temperature

High strength fittings are commonly designed all the way down to -20°F. Extruded outlets are much more diverse. At no extra cost, an extruded outlet can be designed to -50°F. If you have a North Dakota or Canadian project, it is advised you consider -45°C MDMT. Extrusions will be your most economical option for this application due to heat treating and availability advantages. It should be noted, API 5L pipe will require some extra testing for temperatures below -20°F.

5. Field Fabricated (Stick Built) vs. Shop Fabricated

All finger type slug catchers are field fabricated. Some are stick built 100% in the field in varying conditions using tees and pipe and some have the manifolds for their fingers built in fabrication shops. In both cases, at least 25% of the welding on the manifolds occurs in the field and 100% of the line pipe is welded in the field. There is not a single finger type design on the market that is not field built and welded. In general, money is saved by welding the manifolds before they arrive in field because – 1) they can be welded in a controlled environment (not in the dust of the Permian or the cold of North Dakota) 2) Shop welders have lower bill out rates than field welders 3) any PWHT, Radiography, and blast and painting can be done in this same controlled environment without relying on a 3rd party to do your testing (and the PWHT oven is also sitting 30ft away).

When the basis of design is field fabrication, contractors will always recommend 36” or 42” pipe because of speed and availability. Be aware if a field fabricator advises a 10-finger slug catcher with 36” pipe because it’s what they ‘found’ in stock. Utilizing a design with 48” pipe, may allow you to build a 6-finger unit saving significant money. That’s a 20-30% premium you just paid. You’ll need to weigh the delivery vs. the price to come up with the proper decision for your company.