Like all pressure vessels, price and lead time are driven by the size and weight of the vessel. The higher the pressure of the application, the more likely it is to require nonstandard nozzles and plate, leading to higher costs and longer deliveries. The driver of the size of the vessel is directly tied to the operating conditions specified by the facility’s needs. These conditions as well as the metallurgical requirements dictate the material thickness and the overall size and weight of the system. Utilizing the savings from vortex technology’s ability to use velocity to shrink vessel diameters, and Taylor Forge’s ability to manufacture vessels with high strength materials to the ASME Section VIII Division 2 code, it is possible to optimize the design for the cost-conscious customer.

Vortex Advantage

The general tips below will help you achieve savings from the vortex design and Taylor Forge’s ability to manufacture various high strength materials.

- No maintenance. Choosing a vortex separator over one with a vane pack, mesh pad, or filter elements, eliminates the regular costs of these other units. This is particularly true compared to filter-based designs.

- There is no need for quick-opening closure as seen with filter and regular replacement units. The Quick Opening Closure is the most expensive piece to a vessel.

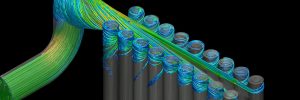

- Vortex can very efficiently deal with high flow turndowns.

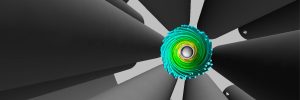

- Reduced vessel size as compared to filter separators, filter coalescers, wire mesh, and vane pack due to increased velocities.

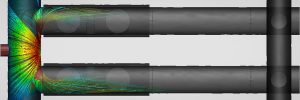

- More efficient than K factor designs.

- Reduced retention times required due to smoother liquid interfaces.

- Vortex designs achieve high efficiency separation (of 99.9% removal of solids down to ≥ 0.3 microns and 99.9% removal of free liquids down to ≥ 1micron) while also being capable of processing slugs or surges of liquids. This should allow you to eliminate additional downstream separators (filters, separation tanks, etc). This is also applicable for slug catchers and other storage vessels where the Vortex separation allows for the reduction in number or required pieces of equipment.

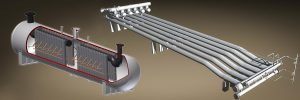

- Design flexibility, units can be oriented both vertically and horizontally.

- Fabricated to the ASME Section VIII Division 2 code to reduce thickness, weight, and price.

Size

- For units with ODs <24” standard pipe will be utilized for the main shell and boot (if necessary). These units will be available with fast lead times, <20weeks

- For units with IDs >24” it all depends on the lead-time for the plate from the mill. For most pressures plate can be procured ‘off the shelf’ or from in stock material, in these cases deliveries can still be achieved in <26 weeks.

- For larger vessels >72” and corresponding higher pressures, the amount of plate required will likely require a mill run. When a mill run is required, deliveries can be as much as 42 weeks for the vessel.

Pressure

- For pressures <1440psig (600#), plate will likely be available in stock. An ASME Section VIII Division 1 vessel will be acceptable and economical.

- For pressures >1440psig (900# and greater), plate will require a mill run.

- As the pressure rises, an ASME Section VIII Division 2 Vessel often makes the most sense. Division 2, because of additional Testing and stress analysis, allows for the use of higher allowable stresses in the base material for your vessel. This means thinner plate and savings.