How is an Extruded Outlet Made?

- Reinforcement calculations done in accordance with design code & submitted w/ drawings for approval.

- Cut & roll plate. Weld longitudinal seam to complete the cylinder.

- Cylinder is laid out with hole locations. Elliptical holes are cut.

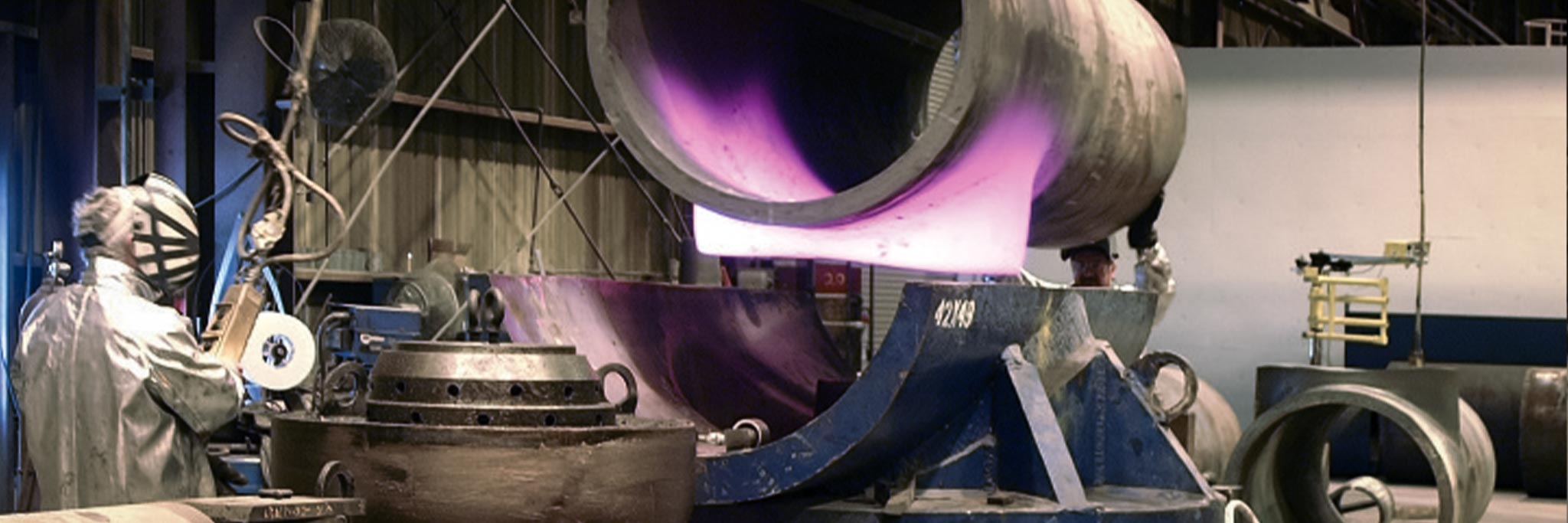

- The extrusion area is heated to 1600°F and moved onto outside die.

- The inside die (punch) is threaded onto mandrel protruding through the cut hole.

- Hydraulic press pulls punch through the hole; sometimes multiple pulls are required to achieve outlet diameter.

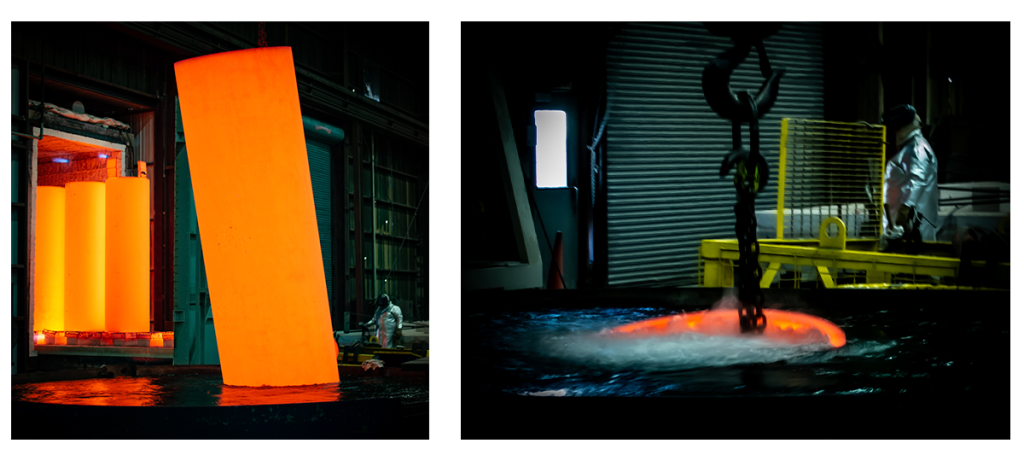

- Header is heat-treated as required by the Manufacturing Code.

- Outlets & run ends are machined.

- NDE – plate is UT’d, pilot holes are MT’d, long seams are RT’d

- Finishing activities include Blast and Paint and packaging. Hydrostatic testing is possible but not recommended to prevent damage to field weld ends.

Heat Treating

To meet the manufacturing specifications above, all fittings must be supplied in heat-treated conditions. Depending on the desired mechanical properties and starting material, fittings must be solution annealed, annealed, quench and tempered, or normalized.

Due to the heating elements of the extrusion process, the starting material becomes critical for proper mechanical properties. Ex: API 5L pipe loses mechanical properties during heat treatment.

Materials

The materials for your extrusion will ultimately be defined by the codes utilized in your project. A MSS-SP75 fitting manufactured to the pipeline codes, requires a base material that meets the MSS-SP75 spec. Similarly, an ASME Section VIII fitting will require a base material from Section 2 of the code.

Manufacturing Capabilities

- Extrusions are typically made from roll and welded plate or pipe up to 84” OD

- Outlets from 1” to 72” OD

- Cylinder wall thicknesses up to 4.0”

- Materials: HSLA up to Y80, chrome alloys, 300 series stainless, nickel alloys, duplex

- Outlets can be pulled radially and tangentially