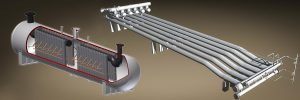

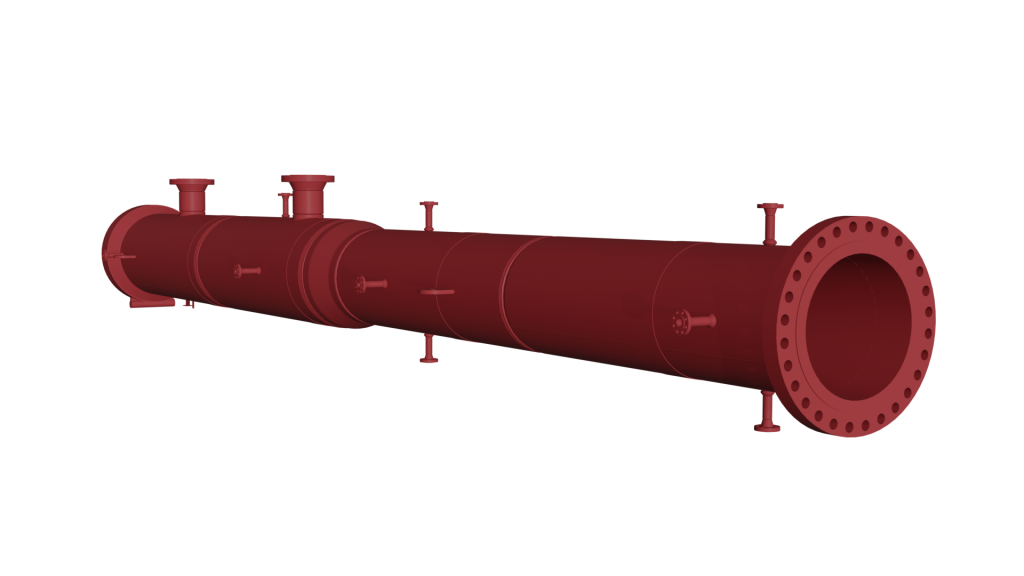

Launchers & Receivers

Helping streamline pipeline performance

Trusted Experience

Taylor Forge has manufactured pig traps, launchers, and receivers for the pipeline industry for over 75 years. Having evolved alongside the industry, we understand the various closure types best suited to your applications. We also recognize the critical importance of reliability and quality, as a poorly designed trap poses a significant risk to operations teams.

INSIGHT THAT PROTECTS

Operating at pipeline pressures means you need the experts to design your Launcher and Receivers to protect your operations team.

SHOP FABRICATION IN A CONTROLLED ENVIROMENT

Fabricating in a shop environment ensures consistent weld procedures and welders working on the life cycle of your equipment build. This ensures consistent, reliable results.

Overview

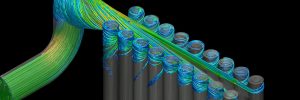

ENGINEERING DESIGN

A fully capable, degreed engineering staff can provide all the design disciplines necessary to complete scraper trap packages like structural design, pipe stress analysis, and instrumentation logic.

METALLURGICAL EXPERTISE

With the expansion of deepwater applications, higher design and operating pressures have pushed the industry to higher strength materials. TFES is a leader in the gas transmission industry in developing new high strength, low alloy steels which meet all the metallurgical requirements of ductility, chemistry, cleanliness, and weldability at yield strengths up to 80,000 SMYS. We stock high strength material that can meet NACE and HIC standards. We have the ability to fabricate traps and assemblies from a variety of alloy materials for other applications including austenitic and duplex stainless steels, chromes, and high nickel alloys.

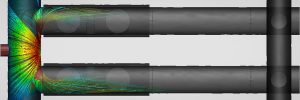

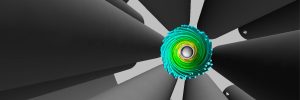

EXTRUDED HEADERS

Traps can experience fatigue stresses due to their pressure cycles. The application of the extruded outlet for the major operational connections results in a low stress joint configuration in a highly stressed area. All fabrication welds can then be radiographed ensuring their quality.